Our Skills

Events

GAMA International exhibits at CIRCLEPACK in Chile

From 16th to 18th April, CIRCLEPACK 2024 exhibition will take

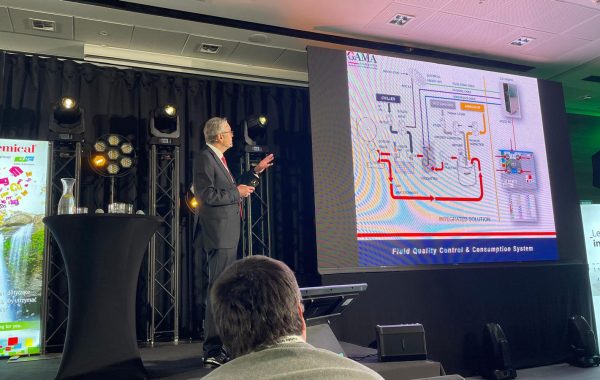

Read moreGAMA International at the Flexographer’s Conference 2024 in Poland

From 18th to 20th March, the Flexographer’s Conference

Read moreGAMA International at the Sustainability In Printing Forum

On 10 September 2024, São Paulo do Brazil will host the

Read moreGAMA International GOLD SPONSOR at FTA Europe Diamond Awards

During Drupa 2024, on 30th May, FTA Europe will host the

Read moreGAMA International at Drupa 2024

From 28th May to 7th June, Drupa 2024 will take place at the

Read moreGAMA International at IPF Bangladesh 2024

IPF is the leading trade event for the plastic, packaging and

Read moreGAMA International at the Uteco Flex-on-Road 2023 tour

During 2023, Uteco launched a major promotional initiative

Read moreI&C-GAMA Group exhibits at Labelexpo Europe in partnership with Sistrade

I&C-GAMA Group participated in Labelexpo Europe 2023, the

Read moreGAMA International Silver Sponsor at INFOFLEX 2023

GAMA International attended at INFOFLEX 2023 as Silver Sponsor.

Read moreGAMA International at K show 2022 in Düsseldorf, Germany – 19th-26th October 2022

GAMA International will participate in the K show, the most

Read more